What are Temporary Works and why are they important?

Temporary works are required for almost every construction project, but understanding what temporary works are and how to manage them adequately is often misunderstood.

The Code of practice for temporary works procedures (BS 5975:2019) defines temporary works (TW) as:

“Those parts of the works that allow or enable the construction of protecting, support or provide access to the permanent works and might or might not remain in place at the completion of the works.”

A simpler definition could be a structure or item of plant that is not self-supporting and could pose a safety hazard if it fails.

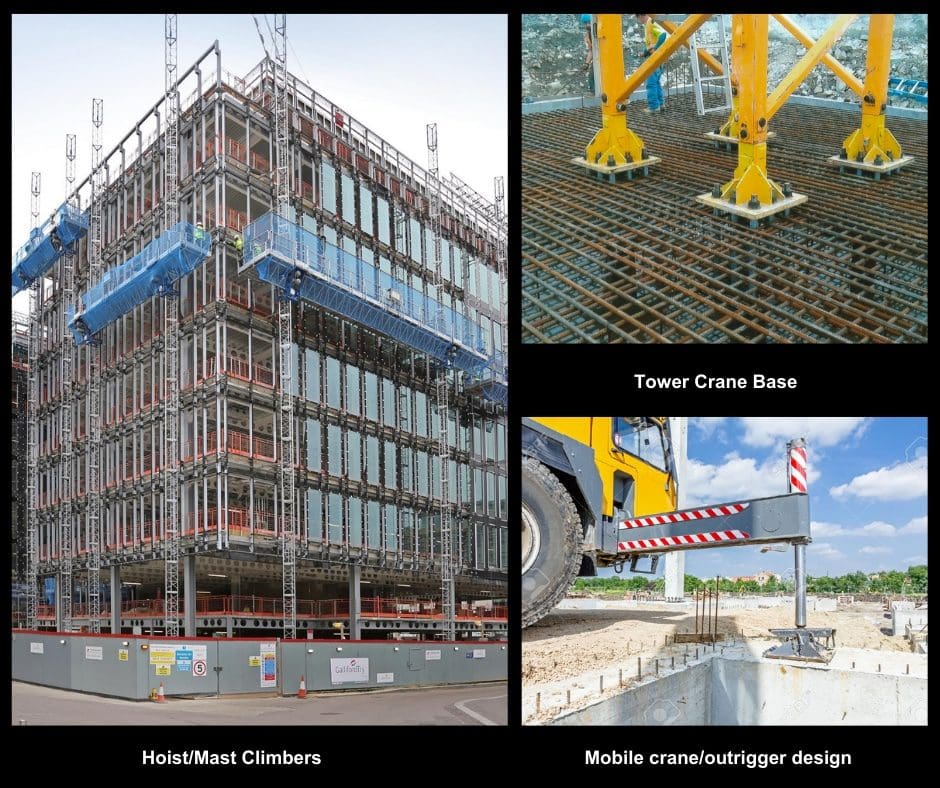

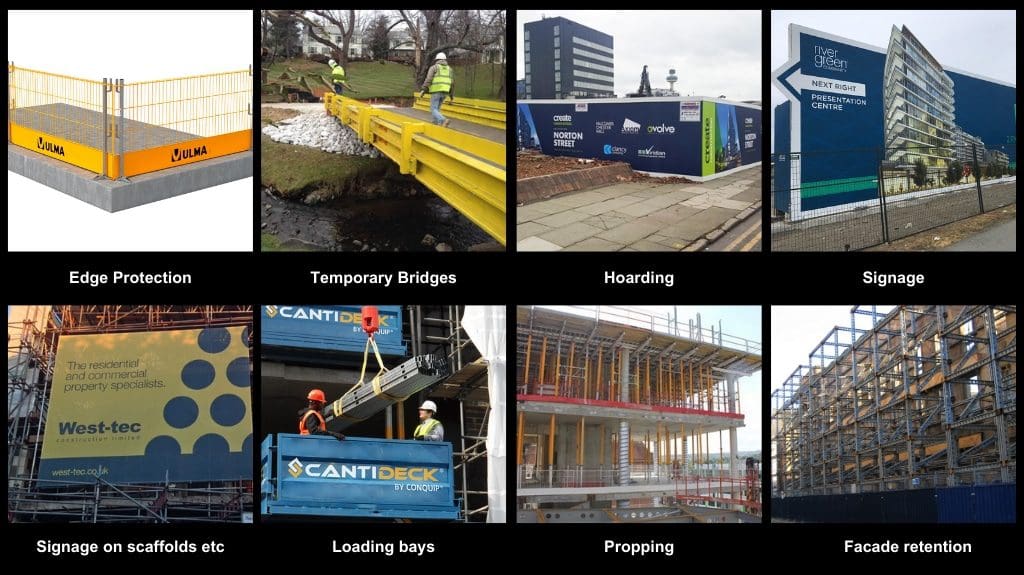

Temporary works are the elements of the construction that are needed to facilitate the construction of the permanent works and will, most often, be removed once construction is complete. Examples of temporary works include:

- Hoarding

- Scaffolding

- Propping

- Shoring and excavation support

- Falsework and formwork

- Cranes bases

- Signs

- Anchors

There may be times when temporary works are incorporated into permanent works. For example, haul road foundations may be used for permanent access roads. However, in the majority of cases, temporary works are only in place during construction. Because of this, the design of temporary works does not always get the scrutiny and diligence required.

A lack of awareness or poor planning of temporary works could cause structures to fail or put workers at risk of injury. Incidents, temporary works failures and poor planning will also cause project delays. At the design stage, the PSDP, along with the design team, should identify expected temporary works for the project. Based on this information, the PSCS should create a Temporary Works Register to monitor and manage all the temporary works required for the project.

Temporary Works Coordination

To manage the various elements, it is necessary that a competent person is in place to plan and be responsible for temporary works. While it is not a legal requirement, it is good practice to appoint a Temporary Works Coordinator (TWC).

On small projects, with simple temporary works needs, a TWC may not be required. However, to ensure safety, you must still ensure that the TW is effectively managed and that all involved are suitably trained.

Often, the temporary condition can be managed by using a particular method and sequence to carry out work, i.e. if the structure and the site can be kept in a safe condition and safe access throughout the process, then plant, equipment and non-permanent works may be minimised or not required.

This means that permanent works designers play a critical role in determining the number of temporary works a project will require. Selecting a build method, sequence, system of work, associated equipment and a suitable workforce involves making decisions based on a large number of variables.

Temporary Works Process

Temporary Works Design

All items of temporary works must be designed. However, in many cases, this is a standard design or specification from a product manual. E.g. standard scaffolds or hoarding systems. However, there are many unique items, and bespoke scaffolds or hoardings, where a design is required. For a temporary works design to be developed, it is essential that there is coordination between the Temporary Works Designer and Permanent Works Designer, with this process aided by the PSDP.

The ORS Health and Safety Management Team have highlighted the stages that should be followed:

- Item of temporary works identified.

- Brief of requirements for temporary works developed

- PWD provides information on permanent works

- TWD designs item of temporary works.

- TWD communicates design with assumptions to PWD

- PWD reviews the interface of TW with PW and any impact on permanent works.

- Steps 4 to 6 repeated as necessary.

- Temporary Works Design and Certificate signed by TWD, PWD (where applicable) and PSDP

- Temporary works erection proceeds, with a suitable method statement in place

- Temporary works used to facilitate construction

- Temporary works taken out of use. Left in place or dismantled/removed.

Temporary Works Design Cert (TWDC)

The item of temporary works should only be constructed when a TWDC is in place and has been signed by the Temporary Works Designer and PSDP to confirm design coordination has taken place.

PSDP

The item of temporary works should only be constructed when a TWDC is in place and has been signed by the Temporary Works Designer and PSDP to confirm design coordination has taken place.

The Project Supervisor for the Design Process (PSDP) has an important role in coordinating temporary works design and installation during the construction stage of a project. The PSDP ensures that all relevant designers are involved and contribute to the safe design process of the temporary works.

ORS are experts in performing the role of PSDP in complex and bespoke construction projects in Ireland and are ideally placed to advise the client, design team and the PSCS on identifying temporary works when designs are required and coordinating the process to ensure that the permanent works can continue safely.

Typical examples of Temporary Works

Earthworks

Typical examples of Temporary Works

Plant

Typical examples of Temporary Works

Structures

If you would like to learn more about our PSDP services, please contact us today at info@ors.ie.